In recent years, with the increasing requirements for sterilization in healthcare, laboratories, and food processing, Steam Indicator Strips Tape has gained wide attention as an efficient and convenient monitoring tool. Through clear color changes, it helps users quickly determine whether items have undergone effective high-temperature steam sterilization, ensuring the reliability of the process.

Content

Core Role of Steam Indicator Strips Tape

In medical sterilization, laboratory equipment preparation, and food packaging disinfection, high-temperature steam sterilization remains one of the widely used methods. However, relying solely on equipment parameters cannot fully guarantee sterilization effectiveness, which is why additional monitoring tools are necessary. Tape was developed to meet this demand.

Its core functions include:

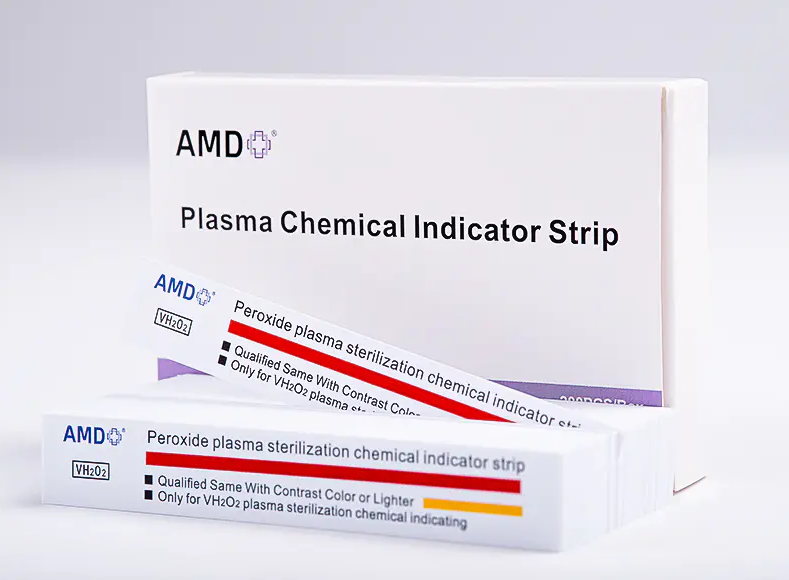

1.Real-time visual monitoring: The chemical indicator on the tape changes color under specific steam conditions (for example, from light to dark), allowing users to quickly verify whether the sterilization process has reached the required standard.

2.Ease of use: The tape can simply be affixed to the outer packaging of items. After the sterilization cycle, the results are visible without the need for complex devices.

3.Support for compliance verification: In industries with strict sterilization standards, such as medical device processing, this product serves as a preliminary validation tool, working alongside other tests to ensure sterilization effectiveness.

Technical Principle and Industry Applications

The working principle of Tape is based on thermo-chemical reactions. When exposed to saturated steam in a sterilizer, the indicator undergoes an irreversible color change, providing intuitive visual confirmation. This makes it a vital tool in the following industries:

Healthcare: Used for surgical instrument packs, dressing packages, and other sterilized materials, helping staff quickly identify sterilized items.

Laboratories: Applied in microbiological experiments, cell culture, and other research settings to ensure sterile equipment and reduce contamination risks.

Food processing: Used to monitor sterilization of packaging materials and production equipment, thereby safeguarding food safety.

This principle not only improves visibility but also reduces risks associated with mistakenly using non-sterile items. Additionally, the adhesive property ensures packaging security while doubling as a safety marker.

Standardization and Compliance Driving Market Demand

The growing global emphasis on sterilization standards has reinforced the importance of Tape. International guidelines increasingly highlight chemical indicators as part of quality assurance protocols. This trend ensures that the tape remains essential in audits, inspections, and daily monitoring.

Standardization also reduces the risk of misinterpretation. With unified color-change benchmarks, healthcare staff and technicians can interpret results more consistently and accurately.

Market Trends and User Concerns

As industry standards continue to rise, users are setting stricter expectations for the performance of Tape. Current discussions focus on:

1.Accuracy improvement: Some users note differences in sensitivity across products. High-quality indicator tapes must ensure clear and stable color changes under standard sterilization conditions to minimize errors.

2.Complementary use with other monitoring tools: While indicator tapes provide intuitive evidence of steam exposure, complete sterilization verification still requires integration with other methods, such as biological indicators, to enhance reliability.

3.Trends in smart and eco-friendly solutions:

Digital integration: Incorporating smart tags or data recording functions to achieve traceable sterilization processes.

Eco-friendly materials: Developing biodegradable indicator tapes to reduce medical and industrial waste impact.

How to Select Reliable Products

For decision-makers, the following factors are crucial when choosing Steam Indicator Strips Tape:

1.Compliance certification: Whether the product meets industry standards to ensure acceptance of results.

2.Performance stability: The tape should maintain consistent color change across real application environments, avoiding errors caused by batch variation.

3.Application suitability: Different sterilization conditions may require specific models, so selection should align with actual operational needs.

As an essential monitoring tool in sterilization processes, Steam Indicator Strips Tape plays an irreplaceable role in enhancing safety and operational efficiency. With advancing technology and more specialized market demand, future developments are expected to focus on greater sensitivity, digital integration, and sustainable materials. These innovations will continue to strengthen reliability in healthcare, research, and food industries.

English

English Français

Français Deutsch

Deutsch Nederlands

Nederlands

‘s-Gravenweg 542, 3065SG RotterdamThe Netherlands

‘s-Gravenweg 542, 3065SG RotterdamThe Netherlands

+31 (0)10 254 28 08

+31 (0)10 254 28 08