In the modern manufacturing and packaging industry, automatic sealing machines play an indispensable role. With continuous technological progress and diversified market demands, Hopeway AMD has been consistently innovating in the field of automatic sealing machines, promoting developments in device intelligence, energy efficiency, and multifunctionality. These advancements not only enhance production efficiency but also meet the stringent requirements for high-quality packaging across various industries.

Types and Application Fields of Automatic Sealing Machines

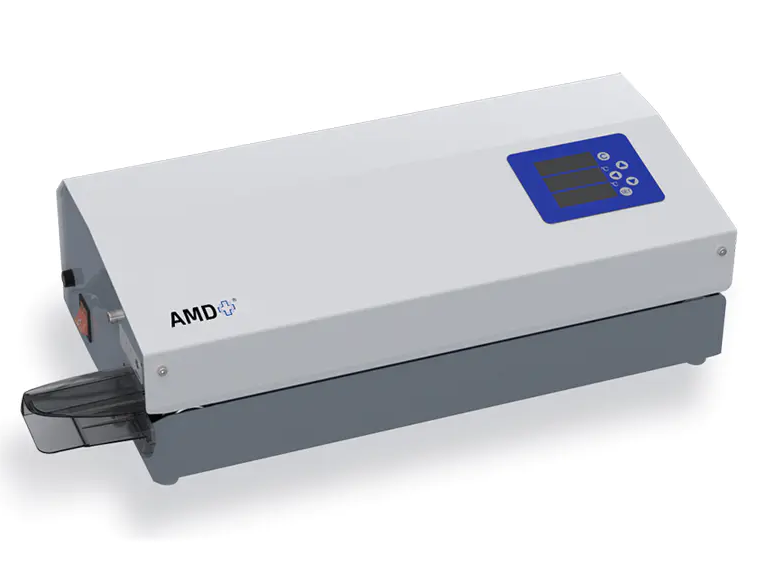

Automatic sealing machines come in various types, each designed to meet specific packaging needs. Heat sealers use heat to bond packaging materials, widely applied in food and pharmaceutical industries to ensure product safety. Vacuum sealers remove air before sealing to extend shelf life and prevent oxidation or bacterial growth. Band sealers are suitable for continuous production lines, often used for electronics and daily necessities packaging to boost efficiency. These machines are equipped with precise heating and pressure control systems tailored to different materials and processes, guaranteeing sealing quality and speed. They play a crucial role in food processing, pharmaceuticals, electronics, and consumer goods industries, safeguarding product integrity and customer satisfaction.

| Type of Sealing Machine | Description | Common Applications |

| Heat Sealer | Uses heat to seal packaging materials | Food, Pharmaceuticals |

| Vacuum Sealer | Removes air before sealing | Food preservation, Medical supplies |

| Band Sealer | Continuous sealing for high-speed lines | Electronics, Daily consumer goods |

Improving Production Efficiency

Automated sealing machines significantly enhance the overall efficiency of production lines and have become an essential tool for modern manufacturing enterprises to boost capacity. By reducing reliance on manual labor, automated sealing machines not only lower labor costs but also minimize errors and inconsistencies caused by human operation. The mechanized sealing process operates at speeds far exceeding manual sealing, enabling large-scale, continuous production while maintaining sealing quality. The high stability and repeatability of the equipment ensure consistent sealing quality for every package, avoiding rework and material waste caused by defective seals, thereby improving overall production efficiency. Moreover, automated sealing machines can seamlessly integrate with other automation equipment such as conveyors and labeling machines to form a complete production line system. This helps companies shorten production cycles, respond quickly to market demands, and strengthen their competitive advantage. As production scales increase, automated equipment further demonstrates cost-effectiveness and high output, becoming a core driver of enterprise growth.

Importance of Sealing Quality and Inspection Technologies

Sealing quality directly affects product safety, shelf life, and customer experience, making it a critical indicator in packaging. Modern automated sealing machines use advanced temperature control systems, pressure adjustment devices, and timing modules to precisely manage the sealing process, preventing defects caused by overheating or insufficient pressure. After sealing, visual inspection systems automatically scan seal lines to detect damages, wrinkles, or unsealed areas, ensuring each package meets quality standards. Pressure testing and leak detection simulate transportation and storage pressures to verify seal integrity, preventing air, moisture, and contaminants from entering. Real-time monitoring and feedback allow companies to adjust machine parameters promptly, continuously optimizing production quality, reducing defect rates and returns, and protecting brand reputation. Efficient inspection systems also comply with stringent industry regulations, serving as indispensable quality assurance tools for modern packaging enterprises.

Energy Saving and Environmental Trends

With the widespread adoption of green manufacturing concepts, the energy efficiency and environmental performance of automated sealing machines have become key focuses of research and development. Designs increasingly incorporate high-efficiency motors and heating elements while optimizing sealing processes to complete tasks with minimal energy consumption, effectively lowering operational costs. Automated sealing machines have also improved compatibility with environmentally friendly packaging materials, supporting sealing of biodegradable films and recyclable composites to help companies reduce plastic waste and meet environmental policies. Intelligent energy management systems optimize sealing cycles and power use, avoiding overheating and resource wastage to achieve green and energy-saving goals. Additionally, efforts in production and material usage aim to lower carbon emissions and environmental impacts. Energy-efficient and eco-friendly sealing machines not only help reduce operational expenses but also enhance corporate social responsibility and brand image. This aligns with increasingly strict regulations and consumer demand for sustainable products, making energy-saving solutions an irreversible trend in the industry.

Intelligentization and IoT Integration

Intelligent technologies and Internet of Things (IoT) integration are critical directions for the future development of automated sealing machines. Through device networking, production managers can remotely monitor machine operating status in real-time, accessing key data such as temperature, pressure, speed, and fault conditions, enhancing transparency and controllability of the production process. Automated equipment can automatically adjust sealing parameters based on production needs, enabling flexible manufacturing to accommodate different products and materials. Fault diagnosis features provide early warnings of equipment abnormalities, preventing production interruptions and saving maintenance time and costs. Remote maintenance and software upgrades reduce reliance on on-site technicians and improve service efficiency. Furthermore, combining big data and artificial intelligence analysis enables smart sealing machines to optimize production flows, predict equipment lifespan, and implement predictive maintenance and resource allocation. The introduction of intelligent manufacturing technologies not only improves equipment performance but also promotes enterprise digital transformation and Industry 4.0 development, making production more flexible, efficient, and intelligent.

Matching Sealing Materials with Equipment

The choice of sealing materials plays a crucial role throughout the packaging process, as the physical properties of different materials dictate necessary adjustments in sealing parameters. Sealing materials such as plastic films, aluminum foil, and composite films each have distinct melting points, thicknesses, and flexibility, which affect the required temperature, pressure, and sealing speed. Automated sealing machines must be precisely calibrated for the specific material to ensure the seal is both secure and does not damage the packaging structure or its contents. For example, aluminum foil seals typically require higher heating temperatures and pressure to ensure quality bonding, while softer plastic films demand moderate temperature and pressure to prevent damage from overheating. Compatibility between the equipment and materials influences sealing stability, aesthetic appearance, production efficiency, and failure rates. Properly matching sealing machines with packaging materials maximizes overall production line performance, guarantees product safety and package integrity, and enhances consumer satisfaction.

Maintenance and Troubleshooting

Stable operation of automated sealing machines relies on meticulous routine maintenance and timely troubleshooting. Maintenance includes cleaning mechanical components, lubricating transmission systems, and inspecting electrical parts to prevent faults caused by dust accumulation, insufficient lubrication, or aging wiring. Common issues such as uneven seals, machine jams, or motor overheating can severely affect production efficiency. Systematic troubleshooting procedures enable operators to quickly identify root causes and implement repairs promptly. Additionally, companies should provide operator training to equip personnel with basic maintenance and emergency handling skills, minimizing downtime. Regular replacement of worn parts and adjustment of machine settings not only prolong machine lifespan but also maintain consistent sealing quality. A scientific maintenance program is foundational to sustaining efficient, continuous production, helping enterprises improve production management and product quality.

New Sealing Technologies

With ongoing technological advancement, emerging sealing methods such as laser sealing and ultrasonic sealing are gradually applied in industrial packaging to meet demands for high precision and specialized materials. Laser sealing uses a high-energy laser beam to accurately heat sealing areas, achieving non-contact sealing ideal for thin films and sensitive packaging materials, thereby avoiding heat damage and deformation caused by traditional heat sealing. Ultrasonic sealing relies on high-frequency mechanical vibrations to generate heat rapidly, melting sealing materials with advantages including energy efficiency, high speed, and pollution-free operation. These technologies not only enhance the appearance and reliability of seals but also expand the application range of automated sealing machines, especially suited for electronics, pharmaceuticals, and other industries requiring sealing quality. As costs decrease and technology matures, these advanced sealing methods are expected to see wider adoption, driving innovation in the packaging sector.

Innovative Applications in E-commerce Packaging

The rapid growth of e-commerce has increased demands for flexibility and diversity in packaging solutions. Automated sealing machines play a key role in e-commerce packaging by accommodating small batch sizes, multiple product types, and varied packaging specifications. Modern sealing machines offer rapid parameter switching and adaptability to different package sizes and shapes, fulfilling the dual needs of quick shipping and personalized packaging. These machines not only ensure sealing speed and stability, boosting shipping efficiency and reducing packaging damage rates, but also integrate with warehouse and logistics systems to enable automated order processing and digital packaging management. The flexibility and efficiency of automated sealing equipment help e-commerce businesses shorten turnaround times and improve customer satisfaction, further advancing packaging toward intelligent and digital transformation.

Market Status and Future Outlook

The global automated sealing machine market has maintained steady growth in recent years, benefiting from increased automation in manufacturing and expanding packaging demands. Market development varies by region due to differences in industrial structures and regulatory environments, but the overall trend favors multifunctional, energy-efficient, and intelligent equipment. Future machines will emphasize compact designs and environmental sustainability to meet the goals of sustainable development. Meanwhile, technological innovation will continue to drive enhanced intelligence in sealing equipment, including IoT integration, big data analytics, and artificial intelligence applications, improving adaptability and production transparency. Competition within the industry will intensify, pushing companies to optimize technology and services to satisfy diversified market needs. Looking ahead, the automated sealing machine industry is poised to explore broader growth opportunities driven by digital transformation and green manufacturing, assisting manufacturers in upgrading packaging automation and enhancing comprehensive competitiveness.

English

English Français

Français Deutsch

Deutsch Nederlands

Nederlands

‘s-Gravenweg 542, 3065SG RotterdamThe Netherlands

‘s-Gravenweg 542, 3065SG RotterdamThe Netherlands

+31 (0)10 254 28 08

+31 (0)10 254 28 08