In the field of medical packaging, sterility and material durability are of paramount importance. As a high-performance packaging solution, the Tyvek Flat Roll Pouch has gained wide adoption in the medical device, pharmaceutical, and laboratory sectors due to its unique material properties and flexible design. This article explores its core applications, structural advantages, material characteristics, and market adaptability to help industry users better understand its value.

Content

- 1 Primary Applications of Tyvek Flat Roll Pouch

- 2 Design Differences Between Flat Roll Pouches and Preformed Pouches

- 3 Tyvek vs. Paper or Film: Differences in Sterile Packaging

- 4 Durability of Tyvek: Puncture and Tear Resistance

- 5 Advantages and Potential Limitations of Tyvek Flat Roll Pouch

- 6 Usage and Adaptability

- 7 Why Choose Tyvek Flat Roll Pouch?

Primary Applications of Tyvek Flat Roll Pouch

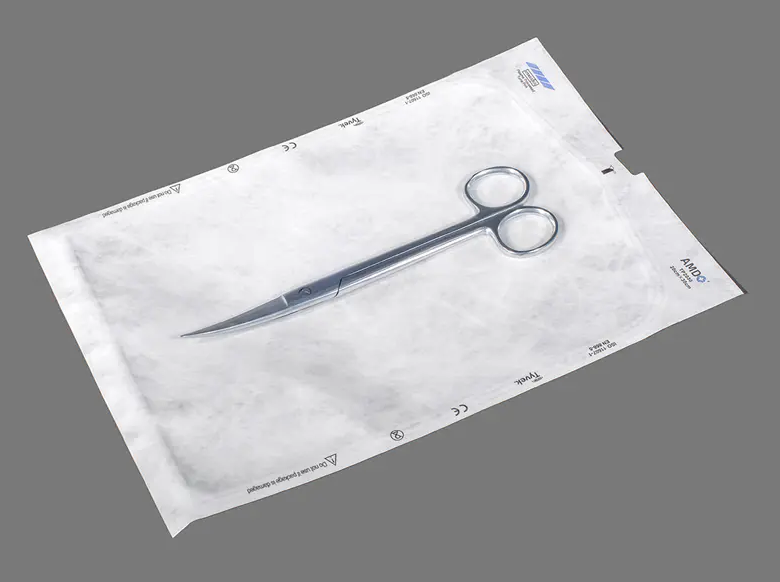

The Tyvek Pouch is mainly used for the sterile packaging of medical devices and consumables, and is compatible with multiple sterilization methods such as steam sterilization (including autoclave), ethylene oxide (EO), and gamma irradiation. Its design allows users to cut and seal according to specific needs, making it suitable for packaging medical instruments of varying sizes such as surgical tools, catheters, and implants. Compared with traditional preformed pouches, flat roll pouches provide greater flexibility and are especially advantageous for production lines requiring customized packaging.

Design Differences Between Flat Roll Pouches and Preformed Pouches

Tyvek Flat Roll Pouches are supplied in roll form, allowing users to cut and heat-seal bags as required, whereas preformed pouches are pre-sized and fixed in dimension. The flat roll pouch offers several advantages:

Flexibility: Accommodates instruments of different sizes, reducing inventory pressure.

Cost Optimization: Minimizes waste caused by size mismatches.

Production Efficiency: Well-suited for automated packaging lines, improving sealing speed.

By contrast, preformed pouches are better for standardized products but lack the adaptability of flat roll pouches.

Tyvek vs. Paper or Film: Differences in Sterile Packaging

Tyvek is made from high-density polyethylene fibers and combines the breathability of paper with the durability of plastic, giving it outstanding performance in sterilization packaging:

| Property | Tyvek | Medical Paper | Plastic Film |

|---|---|---|---|

| Breathability | Excellent, allows sterilant penetration | Good | None (requires special vents) |

| Moisture Resistance | High | Low (prone to moisture) | High |

| Tear Resistance | Very strong | Weak | Moderate |

| Puncture Resistance | Excellent | Poor | Moderate |

The microporous structure of Tyvek ensures effective sterilant penetration while blocking microorganisms and particulate contamination—advantages that traditional paper or film materials cannot easily match.

Durability of Tyvek: Puncture and Tear Resistance

The high-strength fiber structure of Tyvek provides exceptional resistance to tearing and puncture:

Tear Resistance: Maintains integrity even under external force, ensuring package protection.

Puncture Resistance: Prevents sharp instruments from breaking through, reducing contamination risks during transport and storage.

Abrasion Resistance: Withstands long-distance shipping and minimizes wear caused by friction.

These properties make it an ideal packaging material for high-risk medical devices such as orthopedic implants and surgical blades.

Advantages and Potential Limitations of Tyvek Flat Roll Pouch

Compared with traditional medical pouches, Tyvek Pouches demonstrate significant advantages in the following aspects:

| Comparison Dimension | Conventional Medical Pouch | Tyvek Flat Roll Pouch |

|---|---|---|

| Size Adaptability | Fixed size | Flexible cutting on demand |

| Durability | Easily punctured | High puncture and tear resistance |

| Barrier Performance | Limited microbial protection | Long-term, stable microbial barrier |

| Sterilization Compatibility | Restricted to certain methods | Compatible with multiple sterilization methods (steam, EO, etc.) |

| Application Scenarios | Mainly for standard devices | Suitable for standard, special-sized, and irregular instruments |

Advantages

Sterility Assurance: Provides a reliable microbial barrier and complies with international standards such as ISO 11607.

Environmental Considerations: Certain Tyvek grades are recyclable, reducing medical waste.

High Adaptability: Suitable for both automated packaging equipment and manual sealing operations.

Potential Limitations

Cost Factor: Tyvek is more expensive than standard medical paper; however, in the long run it reduces losses caused by packaging failure.

Equipment Compatibility: Some older sealing machines may require parameter adjustments to optimize heat-sealing performance.

Usage and Adaptability

How is the actual usage and adaptability of Tyvek?

In daily operations, healthcare institutions simply cut the pouch to the desired length, then heat-seal it to form a compliant package. Its strong adaptability means both standard surgical instruments and complex medical tools can be effectively packaged.

In addition, Tyvek material is compatible with a wide range of sterilization methods, including steam, ethylene oxide, and low-temperature plasma, ensuring that the sterile barrier is maintained while preserving device safety and integrity.

Why Choose Tyvek Flat Roll Pouch?

When medical institutions evaluate packaging solutions, they often weigh safety, flexibility, and cost-efficiency. The Tyvek Flat Roll Pouch has been increasingly adopted for the following reasons:

1.Reliable Barrier: Provides stable microbial protection throughout the sterilization cycle, reducing cross-contamination risks.

2.Flexible Adaptation: Can be freely cut to meet diverse and irregular packaging needs.

3.Durability: Exceptional resistance to puncture and tearing minimizes risks during transportation and storage.

4.Multi-Method Compatibility: Compatible with steam, EO, and plasma sterilization, fitting various clinical scenarios.

5.Long-Term Value: Despite higher unit cost, its ability to reduce device damage and operational redundancy delivers overall cost-effectiveness.

Thus, choosing the Tyvek Pouch is not just an upgrade in packaging material—it is also a deeper commitment to medical safety and sustainable development.

Thanks to its outstanding sterilization compatibility, durability, and environmental benefits, the Pouch occupies an important position in the medical packaging sector. Although its cost is slightly higher, its advantages in safety and efficiency make it a reliable choice for high-end medical packaging. For organizations seeking high-performance sterilization solutions, the Tyvek Flat Roll Pouch is undoubtedly worth consideration.

English

English Français

Français Deutsch

Deutsch Nederlands

Nederlands

‘s-Gravenweg 542, 3065SG RotterdamThe Netherlands

‘s-Gravenweg 542, 3065SG RotterdamThe Netherlands

+31 (0)10 254 28 08

+31 (0)10 254 28 08